While testing the various configurations of brewing equipment and different styles of brewing, I came across an area of concern for a specific equipment configuration: the direct fired mash tun. This is where the heat source is directly applied to (or within) the mash vessel. Can direct heating cause detrimental overheating of your wort? I put it to the test.

Why direct fire your mash tun?

Mash temperature has a direct influence on the fermentability, flavor, and mouthfeel of your beer. Controlling it helps you preferentially select the activity of different mash enzymes and allows you to tune the final wort profile to your liking. Being able to control your mash temperature creates a higher level of consistency across your brew sessions and is an important means of improving your brewing.

There are many ways to maintain a stable mash temperature and perform step mashing at different temperatures including:

- Insulate your tun - you can do this with your Craft Hardware brew kettle and hold your temperature to within 1-2C over 60 minutes. Same goes for the thermport or cooler mash tun. You can raise the temp by infusing the mash with hot water.

- A HERMS system circulates your wort through a heat exchanger submersed in hot water

- A RIMS system circulates your wort through a tube into which a heating element has been mounted.

- A direct fired mash kettle uses a heating element in the kettle, or a gas or electric burner underneath.

Option 1 is a good way to go, especially if you like to keep things simple. It can also be the lowest cost option. Options 2 & 3 get more complicated and costly, but are much more fun to build and operate and provide better results - in my opinion. The additional cost may dissuade you, which is why I want to consider option 4 in this post.

Direct firing a mash tun makes sense when you want to maintain a stable temperature or perform step mashing while minimizing your equipment costs.

You need to keep the wort moving in this scenario (explanation below), most folks achieve this by either hand stirring, motorized mixing, or pumping. I've always been a "pumped wort" kind of guy, and never really got into the motorized mash tun mixers, but more on that in another post.

In this post I'll be focused specifically on testing a direct fired BIAB system. With this setup, everything is done in one kettle: mashing, lautering, and boiling. There is only one heating element, and arguably you don't even need a pump, if you don't mind stirring while heating. It's a great way to start with all grain brewing, and it's still my go to method about half the time.

However, I was never entirely comfortable using direct fire methods, and had concerns about 2 potential issues: prematurely denaturing enzymes through local overheating, and scorching the wort.

Enzyme Denaturation

In regard to prematurely denaturing enzymes, the level of concern depends partially on your interpretation of the science behind enzymes. Most sources seem to agree that denaturing of beta and alpha amylase occurs more rapidly at higher temperatures, but the process is very much a function of time. Even a minute or two at elevated temperature may have a minimal impact on the overall quantity of available enzymes. Kai over at Braukaiser has an interesting read on the subject, as does Chris Colby at Beer & Wine Journal.

As long as one keeps the wort moving, the enzyme molecules in suspension should not see any significant amount of time at elevated temperature before moving back into the cooler wort away from the heat source. Seeing as to how I and many others have used direct fire many times without suffering from poor mash conversion or fermentability issues, I'm going to guess that as long as the wort is in motion, there is not enough energy there to permanently denature the enyzmes.

Scorching the Wort

It's definately possible to scorch your wort. It's only happened to me once, when recirculating a BIAB setup, the pump flow was restricted and the element dry fired for a minute or two. I was able to catch it early enough to save my element, but the batch was ruined. You could smell that it had burned.

By stirring or circulating the wort while heating, we're trying to move liquid away from the heating source fast enough to help prevent any direct boiling or burning of the wort. Are we at risk of high enough temperatures to cause scorching?

How hot does it get?

I wanted to put this to the test to see how hot it gets around the heating element while using my standard BIAB setup.

I mashed using 31L water and 4.5kG of pilsner malt, with a mill gap 0.04" or 1 mm. Here is the equipment list for my test setup:

- Craft hardware 57L kettle with Brew bag filter

- 3kW heating element mounted in the kettle

- Custom false bottom with 12mm holes mounted 7cm from the bottom of the kettle.

- 6 temperature sensors. 5 in the kettle and 1 in the kettle output (see diagram below). The special false bottom allowed for precise sensor locations.

- TD5 brewing pump, flow control via the output ball valve.

- Craft Hardware kettle mount sparge arm.

- Craft hardware side mount pickup tube

- Custom center mount pickup tube

- Craftbeerpi for heat control and temperature measurement

Sensors installed in FB

Below the false bottom. Notice the side mount and center mount pickup tubes.

Sensors in kettle

Sensor diagram

Mash kettle setup for testing

I ran 6 cycles with the 3 kW heating element: 4 at full power and 2 at 50% power (craftbeerpi fans: I used PIDBoil control for the full power tests, and the SimplePID control for reduced power). I also varied the pump flow rate, and tested the side vs center mount pickups. During each cycle I ramped the wort temperatures from 60C - 65C, after which the wort was allowed to cool again for the next test.

The test results

I've got a picture showing the full set of charts here, in case you are interested. Here is a summary:

- The temperatures measured in the mash tun output (sensor 1) were steady and fairly unremarkable, slowly rising to the desired end temperature of 65C with little to no overshoot in every test. Hurrah!

- There were local heat spots up to 75-80C directly above the heating element (below the false bottom)

- Temperatures in the mash bed were a bit lower, and reached 65-70C during heating.

- Temperatures were lower across the board when using reduced power of 1.5 kW. The 65C target was reached in 9-10 minutes.

- The tests at 3kW power setting all took 5-6 minutes to achieve the target temperature, regardless of the pump flow rate.

- The center pickup resulted in lower temperatures compared to the side pickup, when the flow rate was maxed out at 21 L/min

- The center pickup resulted in higher temperatures compared to the side pickup, when the flow rate was limited to 5 L/min

First of all, setting your pump at full power during mashing is definitely not recommended! It's a good way to compact the grain bed and get a stuck mash, leading to a burned out heating element and a ruined batch of beer. Anyways I'm not really going to discuss those results any further because:

the results showed that for direct fire mashing, restricting the flow rate did not reduce the heating ramp rate.

Now let's take a closer look at the more reasonable - and realistic - flow rate of 5 L/min test results. Here I've charted the average of results for temperature sensors 2-5, which are all below the false bottom in the kettle:

The center pickup tube results showed higher temperatures than the side pickup tube results for a given power setting. I'm not entirely sure why this should be the case. One possible explanation is that there was more friction in the longer center pickup tube reducing flow rate a bit. But even I myself find that not entirely convincing. Further testing would be warranted to get a better answer.

In any case, none of these results overly concern me. The wort is moving freely under the false bottom, and we are nowhere near boiling or scorching temperatures. If you want to play it on the safe side, the lowest temperatures were achieved by reducing the input power to 50%. Considering this cut the ramp rate in half, you will need to be more patient if you choose this approach.

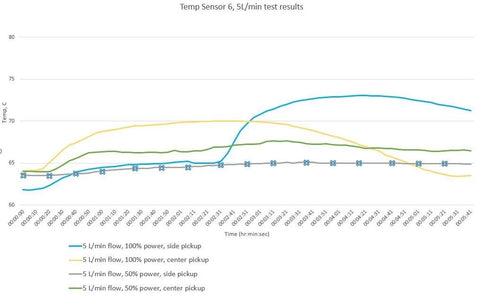

Now let's look at the mash bed temp, from temperature sensor 6, in the center approx 3.5 cm above the false bottom:

Temperatures within the mash bed hit 70C when applying 3kW power to the element. I'm not sure what happened with the blue curve, the other results for that test appear normal, so I'm wondering if there was some sensor error. Regardless: I am not too concerned about these temperatures; wort is circulating through the mash bed as well.

Recommendations

Relax, don't worry, have a homebrew (RDWHAHB)!

But seriously, I'm not too concerned with local temps hitting 75-80C, as long as we keep the wort moving away from this area fast enough. By the time the wort is in the pickup tube temperatures are back within our target range already. Furthermore, I've never had nor have I heard others complaining about unexpected fermentability issues or poor mash conversion when direct heating, so again I see no major reason for concern.

The bigger concern is that the pump flow is reduced or inadvertently stops completely, in which case you will definitely scorch or boil your wort. Take appropriate safeguards such as a flow sensor or a relay to turn of your heating element whenever the pump is turned off (or flow is reduced).

You are welcome to disagree! And even if you just want to play it on the safe side, go ahead and reduce the power of your heat source, or choose another method such as HERMS, RIMS, or just KISS (keep it simple stupid) and insulate your kettle to maintain your mash temps.